Hydraulic Pump Repair: A Complete Guide to Vane Pump Troubleshooting & Cost-Saving Rebuilds

Hydraulic Pump Repair: Why Vane Pump Maintenance Matters

Hydraulic vane pumps are the "power heart" of injection molding machines, construction equipment, and agricultural tools—relying on precise vane-rotor interaction to convert mechanical energy into fluid pressure. When these pumps fail, downtime can cost manufacturers $1,000+ per hour. Yet 70% of vane pump issues are repairable with targeted troubleshooting, avoiding costly full replacements.

Common Vane Pump Faults & How to Fix Them

Vane pump failures often present clear warning signs—here’s how to diagnose and resolve the most frequent issues:

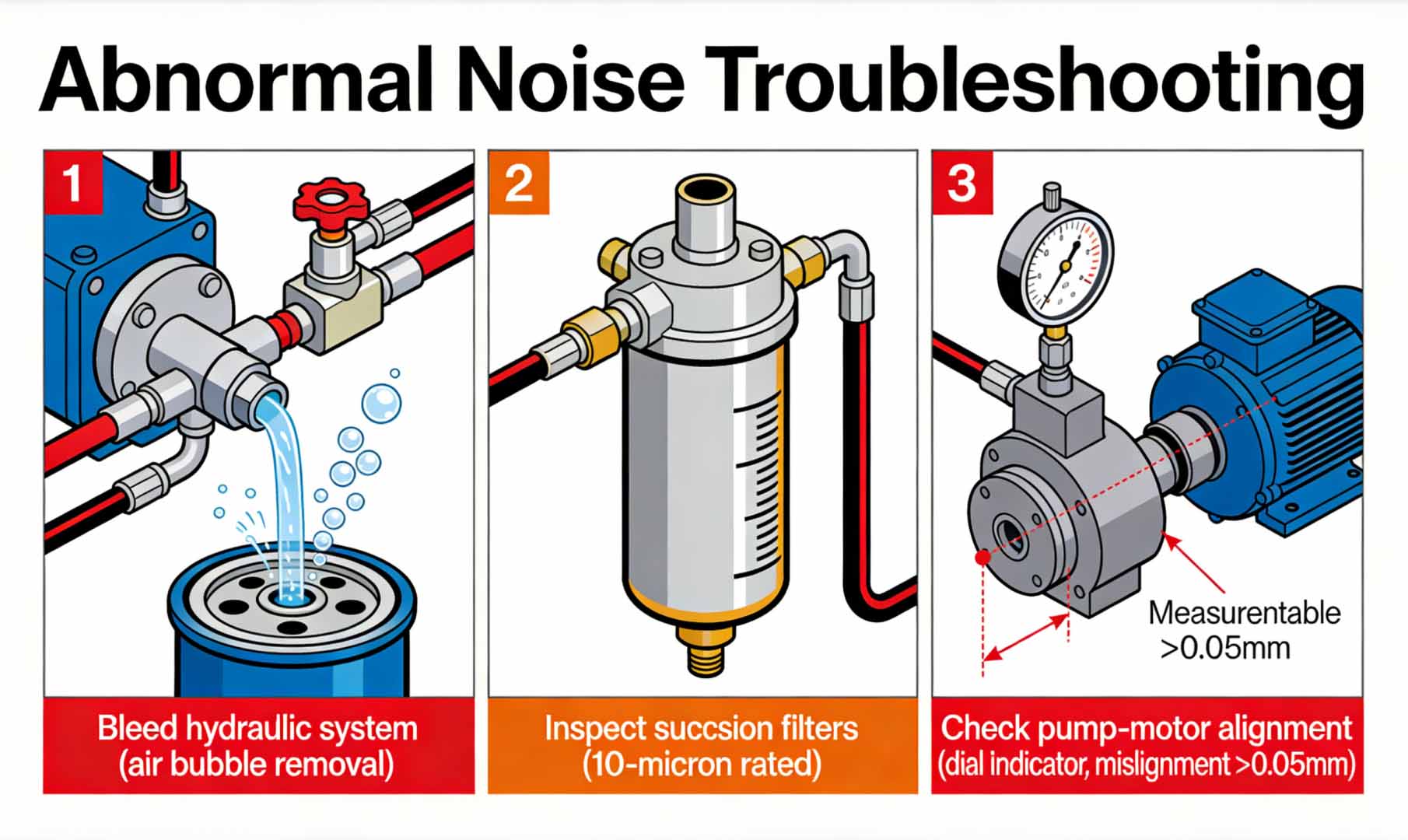

1. Abnormal Noise (Whining/Grinding)

The top cause of noisy operation is air ingress (cavitation) or worn internal components.

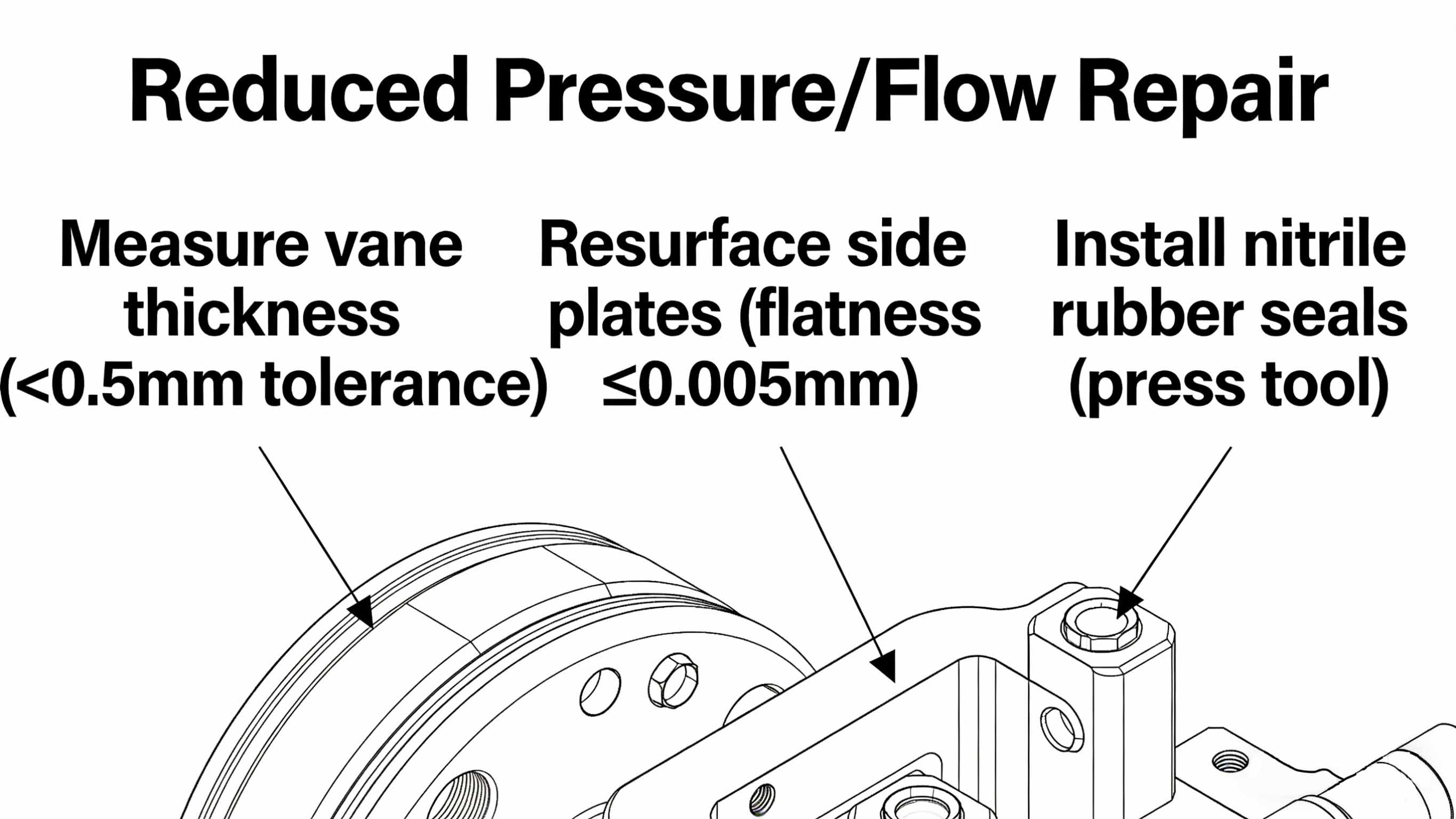

2. Reduced Pressure/Flow

This issue typically stems from internal wear or leakage.

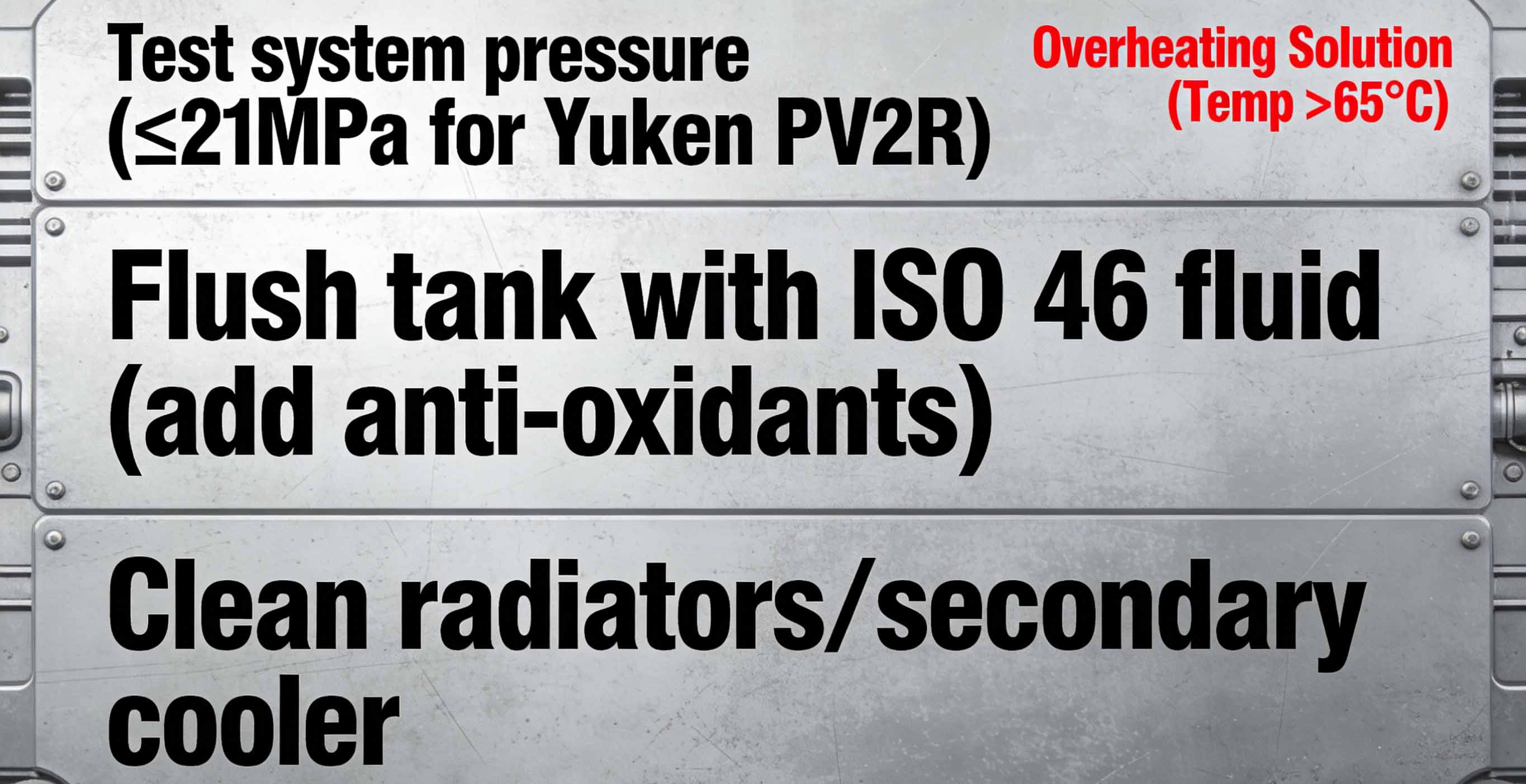

3. Overheating (Temp >65°C)

Excessive heat indicates energy loss from internal leakage or poor cooling.

Repair vs. Replace: Which Saves More?

Repairing a vane pump costs 40–60% less than replacing it, especially for premium brands like Parker Denison or Vickers. Choose replacement only if:

Pro Tips for Extending Vane Pump Life

Preventive maintenance reduces repair frequency by 50% :

Get Expert Support for Hydraulic Pump Repair

Whether you’re fixing a Yuken PV2R or Vickers V20 vane pump, partnering with technicians who offer warranty-backed repairs (12+ months) ensures peace of mind. Contact us today for a free repair quote—most jobs are completed in 1–3 business days to minimize downtime.